PressureMAT™

Additional Products

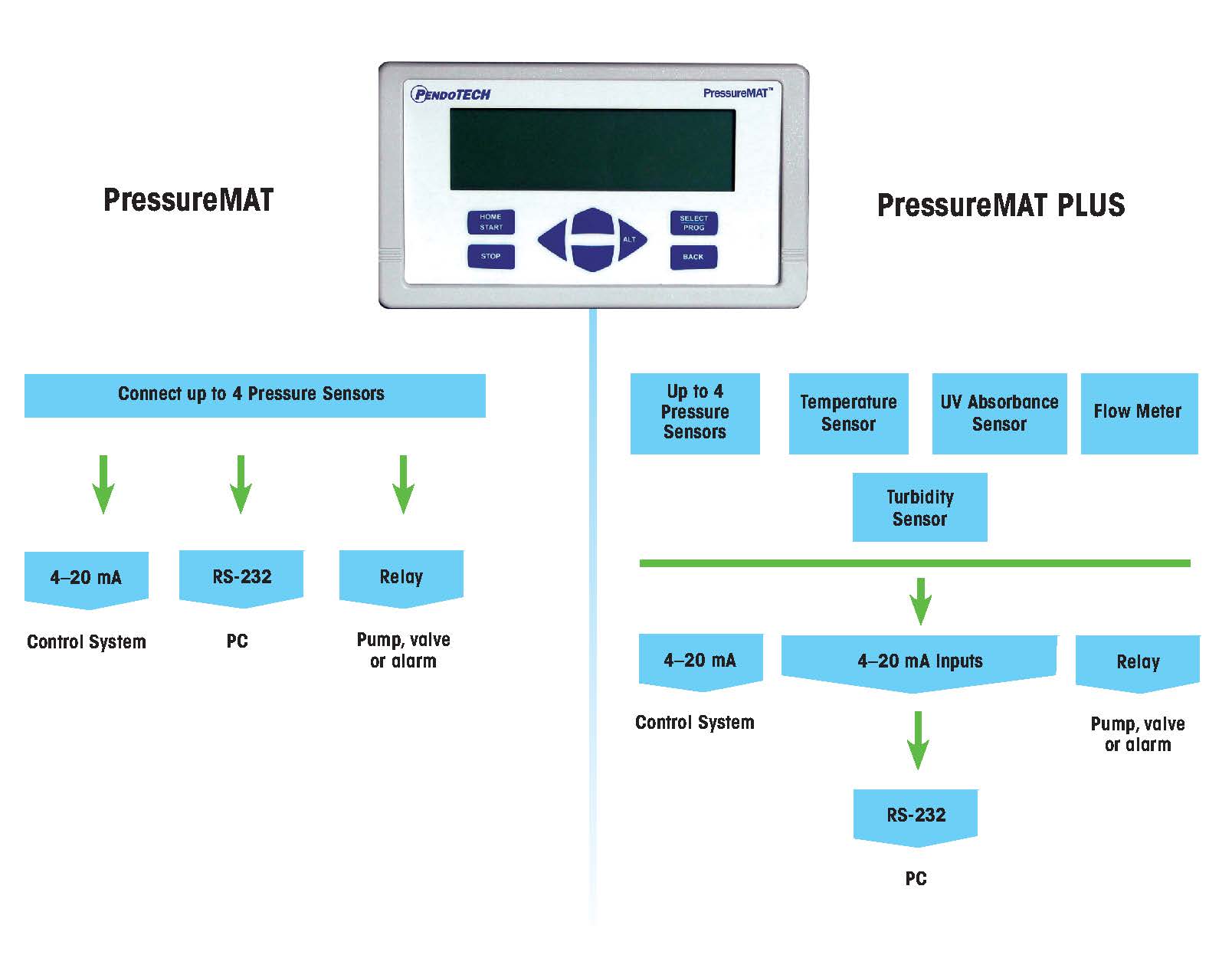

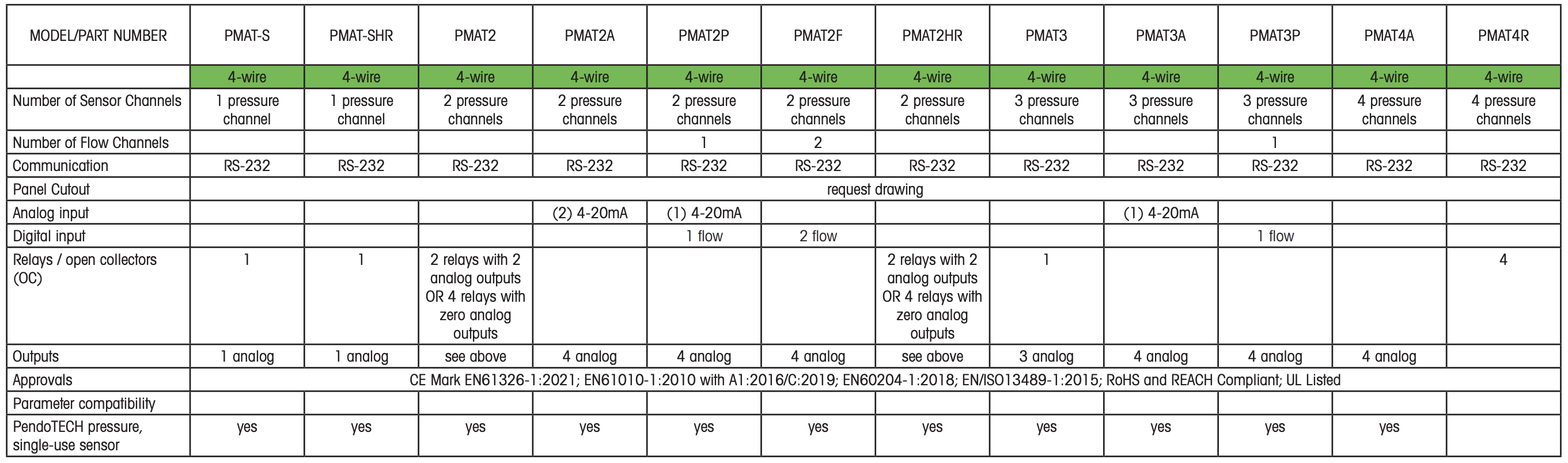

The PressureMAT and PressureMAT PLUS are comprehensive units designed to monitor the pressure of Pendotech’s Single-Use Pressure Sensors. They combine monitor, alarm, and transmitter functions, making them versatile tools for your biopharmaceutical processes. These lightweight, portable units can be easily moved around a lab or pilot plant to the location where pressure measurement is required. They use state-of-the-art, solid-state electronics that require no calibration or maintenance. Their output options allow for easy integration with PCs or higher-level control systems, and a relay switch enables interfacing with pumps and valves. Models are available with up to four pressure sensor inputs. The PMAT3 and PMAT4 models can optionally display Delta-Pressure or trans-membrane pressure (TMP) for filtration processes. These calculated values can also have alarm set points and can be transmitted. The PressureMAT PLUS system comprises the monitor with a user interface and connectors on the back panel where input and output components can be interfaced. It can measure total flow volume in addition to flow rate. Both systems have an alarm function where minimum and maximum values are entered on the keypad. If the process value goes below the minimum setting or above the maximum setting, the system will go into an alarm state. The alarm state may be tied to the relay output to help safeguard the integrity of a process. The transmitter function delivers a 4-20 milliamp output signal corresponding to the process values on the display. The RS-232 data output to a PC is available for data collection to the PendoTECH PMAT Data Acquisition Software. Experience the convenience and reliability of the PressureMAT Sensor Monitor in your biopharmaceutical processes.

Single Channel Unit

Monitor – the process pressure is displayed on the LCD display with a range of -7 to 75 psi. Pressure can also be displayed in bars. The PMAT3 and PMAT4 models can optionally display Delta-pressure of P1-P2 or the trans-membrane pressure (TMP). These calculated values can also have alarm set points and can be transmitted. The PMAT-S Single Channel Unit is available as a High Resolution (HR) model for low pressure applications that achieve 10x the accuracy of the standard unit.

Alarm – minimum and maximum pressures are entered on the key pad and if the process pressure goes below the minimum setting or above the maximum setting, the system will go into alarm state. The alarm state that may be tied to the relay output help safeguard the integrity of a process.

Transmitter – the transmitter function delivers a 4–20 milliamp output signal corresponding to the pressure reading on the display. This system is useful for input to a process control system. Also available is a RS232 data output to a PC and there is Customized Data Acquisition Software that can collect all of the data from the unit, as well as data from one scale – see software demo.There is optional internal data logging.

There are numerous applications in biopharmaceutical production processes where the system can be used to monitor pressure such as filtration, chromatography, and bioreactor pressure monitoring and control.

Ordering information:

Software

-

- PMATP-GUI: Data Acquisition and Trending Software for PressureMAT and CMONT with 2 USB/serial cables to connect to a PC

- PDKT-DLOG: PressureMAT Internal Data Logger

Stands

-

- PMAT-STND: Bench top stand for PressureMAT

- PMAT-STND-MFLS: PressureMAT stand to mount on top of Masterflex L/S Pump

- PMAT-STND-WM5: PressureMAT stand to mount on top of Watson Marlow 500 Series (green) Pump

Water Tight Enclosures

-

- PMAT-WALL: PressureMAT water-tight wall mount box with water-tight cable connections for PMAT2, PMAT3, PMAT4. (click here for picture)

- PMAT-WALL-2: PressureMAT water-tight wall mount box with water-tight cable connections – holds 2 PressureMATs

- PMAT-WALL-S: PressureMAT-S single channel water-tight wall mount box with water-tight cable connections for PMAT

- PMAT-BNCH-IP-L: PressureMAT water-tight bench top stainless steel box with water-tight cable connections for PMAT on left side

Cables

-

- PDKTP-RS232U: RS232 Cable for PressureMAT data output (6feet/2M) for USB input to PC

- PMAT-EXT-12F: Pressure Sensor Extension Cable (12ft)

- PMAT-650-298: Cable adaptor with D15 for Single Use Pressure Sensor for PMAT (12ft/4M)

- PMAT-650-298-24F: Cable Adapter with D15 for Single Use Pressure Sensor for PressureMAT(24 feet/7M)

Pump Start/Stop Cables

-

- PMAT-CB-MF9B: Interface cable for Masterflex LS pump- D9 connector to PMAT to start/stop function, 6feet (2meters)

- PMAT-CB-MF15: Interface cable for Masterflex LS pump- D15 connector to PMAT to start/stop function, 6feet (2meters)

- PMAT-CB-MF18: Interface cable for Masterflex IP pump- 18 pin connector to PMAT to start/stop function, 6feet (2meters)

- PMAT-CB-MF25: Interface cable for Masterflex LS pump- D25 connector to PMAT to start/stop function, 6feet (2meters)

- PMAT-CB-MF31: Interface cable for Masterflex IP pump- 31 pin connector to PMAT to start/stop function, 6feet (2meters)

- PMAT-CB-WM15: Interface cable for Watson Marlow pump-101 and 120 pump with D15 connector to PMAT to start/stop function, 6 feet (2meters)

- PMAT-CB-WM25: Interface cable for Watson Marlow pump- D25 connector to PMAT to start/stop function, 6feet (2meters)

- PMAT-CB-Q1200HT: Interface cable for QuattroFlow Q1200HT PMAT to start/stop function, 6feet (2meters)

Accessories

-

- PMAT-PANEL: PressureMAT Panel Mount Upgrade Kit; 2 gaskets (one and a spare), 4 mounting brackets, sensor cables and connector (one for each input), and power input connector

- PMAT-PANEL-S: PressureMAT-S Panel Mount Upgrade Kit- 2 gaskets (one and a spare), 4 mounting brackets, sensor cable and connector (one for each input), and power input connector

- PMAT-S-DIN: DIN rail mounting kit for PMAT

- PDKT-650-298CVR: Pressure sensor cable dust cover / zero simulator for PressureMAT

- PDKT-650-950: PressureChecker pressure sensor and monitor verification tool, psi

- PDKT-650-950B: Pressure Checker pressure sensor and monitor verification tool, millibar

- PMAT-IQ/OQ: Installation qualification/operation qualification protocol documentation

- PMAT-PWR: Pendotech PressureMAT Power supply with circular barrel connector, 12VDC, 1amp with plugs blades for destination

- PMAT-TCA: Test Cable Assembly for PressureMAT Accuracy Check

- PDKT-PVE2-PMAT-S: Pinch Valve Pair- 24VDC supply & relay input for each normally closed valve- Small for 1/8inch ID

- PDKT-PVE2-PMAT-M: Pinch Valve Pair- 24VDC supply & relay input for each normally closed valve- Medium for 1/4inch ID

- PDKT-PVE-PMAT-S: Pinch Valve- 24VDC supply & relay input for normally closed valve- Small for 1/8inch ID

- PDKT-PVE-PMAT-M: Pinch Valve- 24VDC supply & relay input for normally closed valve- Medium for 1/4inch ID

- PressureMAT Carts: Contact PendoTECH for more details. (click here for picture)

- Pendotech Throttle Valve Data Sheet

The Pendotech PressureMAT (PMAT) monitor/transmitter, designed to read the Pendotech Pressure Sensors, comes standard with a data port. Pendotech has developed a custom software package allowing real-time data trending and collection. This data can be saved to a file and opened with programs like Excel for further analysis. The software includes settings to select the PressureMAT model from a list. It can optionally perform calculated values such as DeltaP and trans-membrane pressure, commonly used in specific filtration applications. Experience the convenience of real-time data monitoring and collection with the Pendotech PressureMAT monitor/transmitter.

PMATP-GUI: Data Acquisition and Trending Software for PressureMAT and CMONT with 2 USB/serial cables to connect to a PC

PressureMAT™ DPG

- Reads Pendotech Single-Use Pressure Sensors™

- Convenient handheld design

- Battery operated

- No calibration required when used with the pressure sensors (the standardized sensor output signal is read)

- One-touch button for sensor tare at 0 psi

- Minimum / maximum pressure display buttons

- Comes with 12foot reusable cable

PressureMAT DPG Specifications

- Reads sensors to their specification of 0-6psi +/- 2% of reading; 6-30psi +/- 3% of reading

- Uses 9V battery (approximate 14 hours of power)

- Auto shutoff after 10 minutes

- Display to x.x psi with updates >2X per second (x.xx upon request)

PMAT-DPG: PressureMAT monitor for 1 single use pressure sensor, battery operated

Data Sheets

- PressureMAT Data Sheet

- PressureMAT PLUS Data Sheet

- PressureMAT Data Acquisition Software Data Sheet

- PTR Transmitter Data Sheet

- Previous GEN Model: PressureMAT Sensor Transmitter Data Sheet

- PressureMAT DPG Data Sheet

- Integrated Single Use Sensor Station Data Sheet

- Power Control via a Relay Data Sheet

- Pendotech Throttle Valve Data Sheet

Technical Notes

- “Pendotech PressureMAT to Yokogawa Paperless Chart Recorder Integration”

- Pendotech Single Use Pressure Sensors: Calibration, Accuracy, and Implementation

- Technical Note: Pendotech Sensors and Industry 4.0: Integrating a PendoTECH Single Use Sensor System with a Digital Highway

Articles

-

- “Measuring Pressure at Very Low Levels with High Accuracy in Single-Use Systems” – Dennis C. Annarelli, Jim Furey, Benjamin Less, and Joshua Huang – BioProcess International 13(3)s, (March 2015)

- “Using In-Line Disposable Pressure Sensors to Evaluate Depth Filter Performance” – Lee R. Bink and Jim Furey – BioProcess International 8(2), (February 2010)

© Copyright 2026 Pendotech

© Copyright 2026 Pendotech